Safety

Factories handling many techniques and processing, HR training supporting thorough quality management system and workplaces.

For us to entirely respond to customer request, our factories can handle many techniques and processing. Besides, both our quality management system and HR training systems are thorough and based on Japanese standards, for our customers to have a complete sense of security.

Facilities

Please click on the links below for more information on our facilities, and more specifically about the administration of our China and Myanmar factories.

Management System

A thorough quality management system based on Japanese standards.

The years of experience of Long Yong, a wholly owned company, are contained in the products we make at our factories. They are the result of various know-hows and management methods. In recent years, we have passed audits for international brands, quality control, as well as safety and labor conditions. Below are the reasons why we offer manufacturing services our customers are satisfied with.

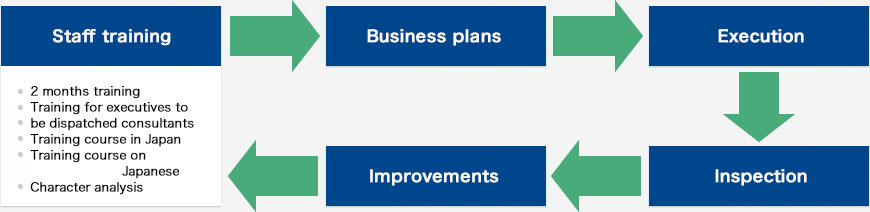

Concept of Management System

- Quality control flowchart

-

-

- 1.Material/accessories storage inspection

- A whole quantity inspection is performed on all materials and accessories delivered, before production. After those of poor quality are removed, the cutting and sewing processes can begin.

-

- 2.Inspection of cut parts

- Cut parts are all inspected a second time at the cutting division. Both face and front are checked, and only those that completely pass the inspection are handed in to the sewing section.

-

- 3.Sewing

- Teams are made up of a line leader, a sub leader and an inspector. The sewing operator is evaluated individually. All this results in the production of faultless goods.

-

- 4. Primary line inspection

- Products are all inspected at the line. Feedback about the contents of daily inspection is immediately transmitted to the line. This process is a way to secure production.

-

- 5.Finished goods / secondary inspection / meter‐reading

- Another inspection of all products is performed in addition to meter‐reading during the final finishing step, for a strict quality control. Then, products with an outstanding quality and functionality are delivered.

-

- 6.Hazardous materials management

- To avoid mixing products with hazardous materials, such as broken needles or scissors used in the production process, we conduct thorough safety control regarding objects used by operators and needle replacement. Records as well as regular inspections are made.

-

HR

A workplace supporting HR Japanese standards.

The origin of our excellent manufacture.

At our factories, quality standards of products for the Japanese market are perfectly understood by our skilled employees working in various sections. Our manufacture is based on safety and trust, since we aim at mutual understanding between Long Yong Japan and the technical and managerial departments.

Regular trainings are conducted in Japan, and people in charge of these trainings completely understand Japanese customers. Making our employees work in a safe environment helps our customers to trust in our manufacture.

The voice of our factory staff

Please watch the video to listen to the voice of our skilled employees in charge of production at our factories.

We encourage each person in charge of a service to enjoy their work, to be motivated and to be responsible.

What is more, as you can see in the video, work environment is clean and perfectly under control.

Corporate Ideology

Corporate Ideology